battery module manufacturing sealing leak test|lithium ion battery cell testing : agent ATEQ has a variety of methods to leak test batteries throughout the production process. Leak testing electrical vehicle battery cells, for example, begins with an ionic leak test of the .

Resultado da Saint Tropez Confeitaria é uma padaria incrível, com um amplo espaço interno e estacionamento amplo no local. Você com certeza terá uma experência agradável por lá. Eles oferecem uma grande variedade de doces e salgados, mas o destaque vai para o pão francês que é um dos mais .

{plog:ftitle_list}

webJehovah's Witnesses is a nontrinitarian, millenarian, restorationist Christian denomination. As of 2023, the group reported approximately 8.6 million members involved in evangelism, .

Testing for leak tightness requires some form of leak detection. Although various leak detection methods are available, helium mass spectrometer leak detection (HMSLD) is the preferred and is being used broadly to ensure low air and water permeation rates in cells.

Ensuring Long-term Battery Performance and Safety. Helium mass spectrometer .MARPOSS offers solutions for leak test and leak detection in all phases of the production process of the batteries: • Helium vacuum test or electrolyte tracing for individual battery cells The new battery-cell leak-testing systems are capable of identifying dangerous leaks 1,000 times smaller than currently possible. They .Ensuring Long-term Battery Performance and Safety. Helium mass spectrometer leak detection provides a precise, repeatable, and easy-to-use method for detecting and measuring leak rate .

ATEQ has a variety of methods to leak test batteries throughout the production process. Leak testing electrical vehicle battery cells, for example, begins with an ionic leak test of the .

marposs battery leak testing

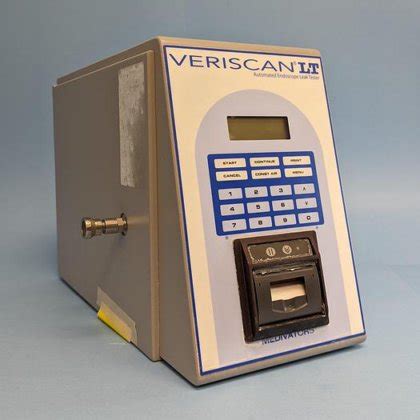

lt hls leak detection

August 1, 2023. Auto manufacturers and suppliers need a valid, reliable way to detect flaws in electric vehicle battery enclosures, or modules. EWI has developed an inexpensive testing method with demonstrated feasibility!Leak testing is a fundamental operation in the battery cell production process, in particular for the new generations of lithium-ion secondary batteries. The perfect sealing of the housing is one of the most important features to guarantee the .To guarantee these requirements, modern battery cells must be leak tested to leaks in the range of a few micrometers in diameter equaling leak rates in the range of 10 -6 mbar*l/s. While air-leak testing is well established, battery pack testing best practices are still evolving. How can manufacturers efficiently and cost-effectively ensure quality and assure consumers that they have nothing to fear when .

The size, structural characteristics and applications of a battery pack present a multi-faceted challenge in devising an appropriate leak test. Battery packs are large and often have flexible surfaces. Uson has identified air leak testing as a viable option to helium leak testing in some EV Battery leak testing applications. English English 简体中文 Deutsch Español . Helium leak testing systems are commonly used in the automotive manufacturing industry. Helium is inert and made of the smallest gas molecules allowing it to pass through . Here, damage or short circuits to the battery cells must be prevented. Leakage coolant from the cooling circuit can cause a battery fire. Independent of the leak tightness required in each respective application .

Disconnect the leak test port adapter from the HV battery. Install a new leak test plug (torque 8 Nm). Remove the rubber plug from the front gore breather hole. Install a new front gore breather and front vent cover cap. Mark . Battery manufacturing processing chain. Source: INFICON. Testing Battery Cells Today. Most quality issues occur during battery-cell production, battery-module assembly or battery-pack assembly. Lithium-ion battery cells must be thoroughly tested to eliminate leaks that might allow water or humidity to enter the cell, or cause electrolyte to .

lithium ion battery cell testing

air leak test with 5 psi air pressure for minimum duration of 3-5 Sec and pressure drop is measured. The Pareto chart shown in Fig.1explain that heat seal leak contributes about 51% of total assembly rejections; the defect level is 0.15 %. The box plot is shown in Fig. 2 represents the pressure drop in normal and heat seal leak batteries. In .We Provide Leak Testing For. Battery cells, modules, and packs. Casting porosity. . In-Line and End of Line Testing. Support a range of leak and seal tests to help identify, remove and fix products early in the manufacturing and assembly process. . Both tests are used in large-volume automotive applications such as battery module and pack .

In conclusion, bubble leak integrity testing is a valuable non-destructive testing technique to identify leaks or faults in sealed systems. It is a widely used method across various industries to ensure the reliability, safety, and performance of components and systems. Procedure for Bubble Leak Integrity Testing: The objective of this study is to reduce the heat seal leak rejection in the lead-acid battery assembly process using Six Sigma's DMAIC (Define, Measure, Analyze, Improve and Control) methodology.Additionally, we established a comprehensive thermal analysis capability that enables us to identify and measure exothermic and endothermic reactions within a lithium-ion battery cell. Testing to battery module and pack testing standards and local country marks. We test and certify battery modules and packs to diverse standards. “A select few are using tracer gas to test their battery packs,” explains Hagyard. “The type of leak test equipment necessary is also dependent upon the size of the battery pack, its flexible nature and the leak rate.” In-Process vs. End-of-Line Testing. Manufacturers use both in-process and end-of-line leak testing.

labrum tear tests

leak test for battery cells With HEV/EV technology comes new leak test requirements for the automotive industry: each single battery cell must be protected, reliably, against any penetration of humidity and air. The MARPOSS helium vacuum test detects leakage rate of 10-3 to 10-6 scc/s. leak test for cooling circuits of battery modules and packsBattery Cell Leak Testing Multiple testing methods are herein presented to quantitatively, deterministically and non-destructively leak test prismatic or cylindrical lithium-ion battery cells. At this time no test method has been codified for finding small leak channels in the battery cells. While the minimum detection limit of theThe InterTech M1075 High Speed Mass Flow Microscale Charge Volume Leak Test Instrument tests 10 Sealed Batteries Variations for IP67 integrity to ensure there is no water intrusion through the life of the product.. InterTech's EV battery pack leak test system (proprietary charge volume leak test circuit) ensures gross leaks are detected immediately and fine leakage is reliably .of automatic leak testing machines & leak test systems for assembly lines or laboratories. FOR YOUR TESTING NEEDS! 49 years after its creation, ATEQ is now a 187 M€ company with offices in 40 countries selling and servicing more than 275,000 leak testers installed in more than 5,000 customers worldwide .

Pouch-type batteries are typically only tested once after final sealing. End-of-line testing of fully assembled hard case battery cells For integrity testing of filled hard case cells (prismatic, round, coin) the process . Learn how to most efficiently leak test lithium-ion battery cells for electric vehicles and mobile devices. Leak testing . He has been a featured speaker at numerous trade conferences on topics related to battery pack design and testing, battery-cell leak detection and leak testing of battery-pack thermal management systems. Parker joined .Marposs can provide a wide range of standard products and customized applications for the leak testing of battery systems along the complete manufacturing chain. From checking the sealing on the cell housing to the .

Battery leakage occurs when chemicals escape from a battery, posing risks to humans and devices. . Place the leaking lithium battery in a non-flammable container to prevent additional leakage. Properly seal the container to minimize the risk of exposure to hazardous chemicals. . overcharging, physical damage, or thermal abuse. Manufacturing . Title: Understanding Helium Leak Testing for Lithium-ion Batteries Introduction: Ensuring the safety of lithium-ion batteries has garnered significant public attention, especially with the .

Our diverse portfolio offers solutions for every test on your line. With our combined in-depth knowledge of leak testing for a variety of applications and large to small leaks, as well as our thorough expertise in in-process testing, our team is equipped with the knowledge and products to test and monitor virtually any manufacturing process on your production line.manufacturing process is performing. Our leak testers accommodate multi-step processes for greater flexibility to meet quality demands. Pioneer of Modern Leak and Flow Testing Lithium-ion Battery Testing Equipment and . battery-module .The Battery EOL Tester supports the entire end-of-line testing workflow by providing customized communication and testing solutions including electrical testing, leakage testing, BMS configuration, etc. In addition, the Battery EOL Tester has a central database for subsequent analysis & traceability of measurement data.Sealing Schedule 3 was developed and used to compare the sealing results for different lots from package and cover suppliers. These packages and covers were from Materials Lot 1. All passed gross leak; fine leak test mean of 4.3E-10 atm-cm3/sec air with Std Dev 0.35.

The battery manufacturing process creates reliable energy storage units from raw materials, covering material selection, assembly, and testing. . Battery module and pack assembly; Part 8. Battery quality control and testing; . 5.4 Sealing. Seal the battery cell once the electrolyte has fully saturated the electrodes. This is a critical step . Step 7: End of Line Testing and Quality Control of the Module. The Modules then will undergo Quality Control where depending on the manufacturer quality criteria various parameters are checked. Insulation, Optical Check, Slave BMS testing, Leakage test for Module Housing, Connectivity Test, Connectors, Charge and Discharge Test, SOC, Thermal etc. Disconnect the leak test port adapter from the HV battery. Install a new leak test plug (torque 8 Nm). Remove the rubber plug from the front gore breather hole. Install a new front gore breather and front vent cover cap. Mark the cap with an orange paint pen.

lithium cell leak testing

Helium Leak Testing: A small amount of helium is introduced into the sealed battery, and a mass spectrometer is used to detect helium leakage, pinpointing the source of any leaks. 3.

WEBView the Menu of BETO Lanches in Taubaté, SP, Brazil. Share it with friends or find your next meal. Venha experimentar o melhor lanche da região. Se preferir ligue e peça no delivery (12) 991146928.

battery module manufacturing sealing leak test|lithium ion battery cell testing